Deck Motion Monitor (DMM)

“Improved safety & lifting efficiency between offshore cranes and vessels”

The DMM system displays the Effective Significant Wave Height, real time waves, live video and images from the supply deck. The Crane Operator can now use accurate wave data from the supply vessel’s DMM as a superior replacement to the traditional Significant Wave Height method used today. Real time video from the supply vessel’s DMM camera gives the Crane Operator another angle view and can cover blind zones on deck.

Using the DMM will significantly increase safety as well as operational availability to offshore lifting operations.

Traditional Method

The traditional method, using wave buoys, radars or manual observation of the sea state, does not take any further consideration to the following:

• The accuracy of the estimated / measured Significant Wave Height (H1/3)

• The variation in wave type and period

• The variation in downward velocity at different deck positions

• The variation in shape, stability and loading condition of the vessel

• The variation in direction of the waves in relation to the vessel heading

By using the DMM all the above mentioned uncertain factors are eradicated. With the DMM system, the Vessel Officer and Crane Operator can make safe decisions based on facts.

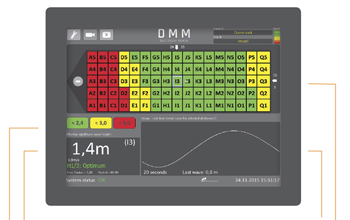

Typical Layout

The DMM consists of a master system onboard the vessel, and a slave unit installed in the crane. All the measurements and calculations are done in the master system, and transmitted wirelessly to the crane.

By measuring vertical deck velocity, and calculating Effective Significant Wave Height at multiple locations, we ensure compatibility with Safe Load Indicators for offshore cranes and wave limits for personnel transfer.

The Crane Operator sets the Safe Load Indicator limits, and the DMM system displays safe and unsafe lifting zones. The Crane Operator can monitor the specific area of the planned lifting operation.

Approval of the DMM Method

Based on the DNV DMM Technical Report a recommendation for use was made applicable to the CEN / TC 147/WGP 5 on the 29.03.2007. WGP 5 is the Working Group within Technical Committee CEN/TC 147 Cranes – Safety, which has developed and also maintains the EN 13852-1 standard.

EMC / Safety / Environmental compliancy:

EN 55022 / EN 55024 / EN 61601-6-2 / EN 301 489-1 / IEC 60945/50-1 / IEC 61508