Drilling Instrumentation

Rig monitoring system (RMS)

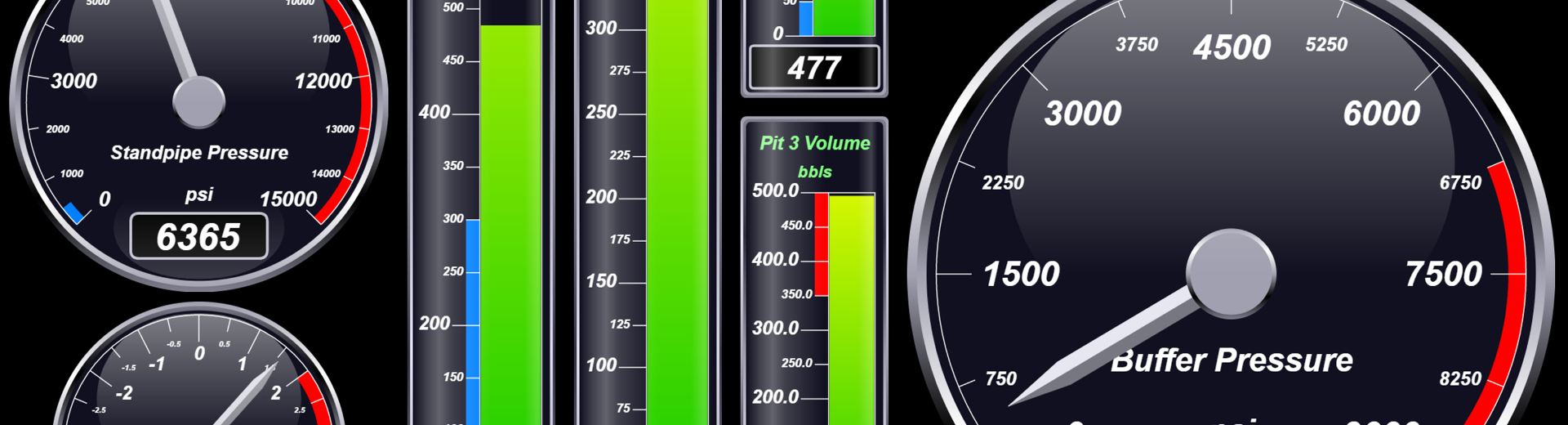

The RMS system is designed to display highly accurate process and read back information derived from an almost limitless range of sensor inputs from drilling equipment. The operators interface is both intuitive and easily configured for each application.

Operators have access to a number of individual screens displaying a wide range of drilling information; the system can also integrate third party systems to include CCTV, motor stop/starts, emergency shutdowns and maintenance & diagnostics stations. Information can be viewed as a trend and all data logged.

The system has been designed to allow expansion should new sensors and equipment be fitted at a later date.

Screens can be adapted to display system information used in the following applications:

Drilling / Tripping / Pumps & Pits / Bulk Storage / Mud Mixing / Anchor Winches / Engine Monitoring / HPHT / Well Control / BOP Functions

Case Study: Rig monitoring system with data acquisition for North Sea Platform decommissioning.

As part of their decommissioning programme a North Sea operator needed to reinstate an obsolete drilling instrumentation package prior to a plug and abandonment programme.

The OEM of the existing equipment had previously surveyed the system which comprised of a multitude of sensors, a microprocessor controller with a separate Data Acquisition unit (DAQ). The system was condemned and would need to be completely replaced. The costs associated with replacing the whole system had not been fully accounted for and on the face of it the clients’ most cost effective solution would have been to lease a new “off the shelf” product from the OEM.

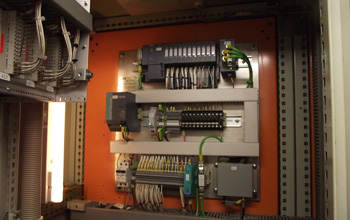

RCP were subsequently asked by the clients engineering representatives to propose an alternative solution, using our wealth of experience integrating new PLC technology with older hardware systems our engineers were able to quickly design a HMI based system utilising many of the older components already in place. Working with the client and their engineering team RCP designed a bespoke operators interface aligned with the clients requirements adding value to the system, a DAQ for logging the rig instrumentation process was built into the design and will log and archive data for approximately 24 months.

RCP were able to design, destruct parts of the original system, install and commission the new RCP system for a cost well below that proposed by the OEM for leasing their equipment for 12 months only.

RCP had proven their worth again in saving costs involved in in both the exploration and decommissioning markets over a lengthy period of time.

This and many other similar projects that RCP have been involved with recently have proved that major operators and drilling contractors alike can find alternative more viable solutions without compromising quality and functionality.